Appleskin is a leather-like material produced by the German company Nuuwaï. The material is entirely vegan, with 50% of it consisting of by-products from the apple processing industry and 50% of PU (Polyurethan). Nuuwaï creates durable accessories from this by applying the apple and PU mixture onto cotton fabric and heating it in order to make the material long-lasting and water-resistant. Appleskin is Peta-Approved Vegan and OECO-TEX 100 certified. |

Bamboo fibre can be extracted using two different methods: mechanical extraction, which results in a fabric that resembles linen (also often called bamboo linen), and chemical extraction, which results in a rayon (viscose) fabric. In comparison to other viscose fabrics, bamboo grows quickly even without the use of pesticides or herbicides. In addition to that, fabric made from bamboo is highly water-absorbent, breathable and anti-bacterial. |

Banana fibre is derived from the pseudostem of the banana plant. It is extremely resource-efficient due to the fact that it is made from waste material that would otherwise be burnt or left to rot. The extraction and processing methods for banana fibre can vary to a great extent, with some being more eco-friendly than others. Depending on those methods, the quality of banana fibre can range from a rough bast fibre to a shiny and soft yarn that is very similar to silk. |

Cork is a natural material that is derived from the cork oak tree, which mostly grows in the Mediterranean and Iberian region. It can be harvested every nine years from the outermost layer of the tree. Cork material keeps its unique surface structure and can be used as a vegan alternative to leather. The material is extremely lightweight, water- and tear resistant. In addition to that, a harvested cork oak tree can absorb up to five times more carbon than one that is not harvested, making the process even more eco-friendly. |

Cupro is a cellulosic fibre that is made from cotton linters. These cotton linters are a by-product of the cotton harvest and consist of fibres that are too small to spin. The manufacturing of cupro requires the use of chemicals, but if produced in the most sustainable way possible, the chemicals are kept in a closed-loop system in order to minimise their environmental harm. Cupro has similar properties to cotton while at the same time being soft and lustrous, which is why it is often used as a vegan alternative to silk. |

Econyl is a regenerated nylon yarn from the Italian recycling company Aquafil. It is made using both post-consumer waste, such as discarded fishing nets, and pre-consumer waste in the form of fabric scraps. The waste is collected from around the world and is treated in Slovenia in a closed loop system into 100% regenerated and regenerable nylon. As well as saving harmful ghost nets from the ocean, this method also uses 50% less energy than the production of virgin nylon. In addition to that it reduces carbon dioxide emissions by 50% and entirely avoids the extraction of crude oil. |

Hemp grows rapidly and uses approximately half the amount of water and land compared to conventional cotton. In addition to that, hemp grows so densely that it is able to crowd out weeds without the help of herbicides. Clothing made from hemp is durable, highly moisture-absorbent and naturally anti-bacterial. The drape and feel of hemp fabric is very similar to linen. |

Milk fibre is made from leftover milk that can no longer be used for food production and would usually be discarded. Instead of disposing of it, companies such as QMilk turn the milk into a protein fibre which is suitable for the textile industry. Milk fibre has a soft and smooth feel and is beneficial for the skin, therefore making it an ideal choice for people with allergies or skin sensitivity. The fibre itself is biodegradable, and clothing made from milk fibre has antibacterial properties and absorbs moisture well. |

Modal is a type of rayon, a cellulosic fibre made mostly from beech trees. While conventional rayon (viscose) is often seen as unsustainable due to deforestation and toxic production processes, the Austrian company Lenzing have managed to create an eco-friendly Modal production process which is entirely based on renewable resources and the recovery of process chemicals. Modal fabric has great mechanical properties since it is breathable and absorbs around 50% more water than cotton. In addition to that, Modal fabric is very soft and has a great resistance to shrinking and pilling. |

Orange Fiber is an Italian company that produces cellulosic fibre and fabric from citrus juice by-products. They thereby make use of some of the 700 000 tons of citrus waste that are discarded alone in Italy every year. The fabric made from this citrus fibre has a very smooth and soft feel and is therefore often compared to silk. Like other cellulosic fabrics, it is breathable, durable and easy to care for. In addition to that, Orange Fiber also contains vitamin C and the same essential oils that are present in the citrus fruit peels. |

Unlike conventional cotton, organic cotton is grown without the use of pesticides, herbicides or other harmful chemicals. While the water usage of organic cotton is still high in comparison to other fibres, its production is using a considerably lower amount of water than conventional cotton. Organic cotton is a natural fibre that is renewable and biodegradable, and clothing made from this fibre is breathable and absorbs moisture well. |

Within conventional silk production, silk cocoons are usually boiled or dried out with the silk worm still trapped inside in order to get an undamaged filament. Peace silk production on the other hand enables the silk worm to either hatch from its cocoon naturally, or the cocoons are cut open so the silk worm can emerge before the fibre is processed and spun. Companies like Cocccon produce GOTS certified peace silk which is manufactured entirely without the use of chemicals and hormones. |

Pineapple fibre is made from the leaves of the pineapple plant, which are an agricultural byproduct of the food industry. The use of pineapple fibre is very versatile. Ananas Anam for example have managed to create a non-woven mesh made from pineapple fibres, which forms the base of Piñatex®. Piñatex® is often referred to as a vegan alternative to leather, and is also more sustainable due to its lower environmental impact. Besides, the production of pineapple fibre creates an additional and stable income for farming communities.

|

Ramie counts as one of the oldest textile fibres and is derived from the nettle plant. It can be harvested up to six times a year and undergoes a process that includes decortication and degumming in order to achieve a spinnable fibre. Ramie belongs to the group of bast fibres and has qualities similar to those of linen. In addition to that, the fibre is bacteria resistant and has a high moisture absorbance.

|

Unlike virgin polyester - which heavily relies on the use of petroleum - recycled polyester uses PET as its base material. PET is the same material which is used in clear plastic bottles, and recycling it into fabric minimises the amount that goes to landfills. In addition to that, the production of recycled polyester only uses about half the amount of energy compared to virgin polyester. Recycled polyester has the same positive attributes as virgin polyester, but is also considerably less harmful to the environment. It is extremely durable, resistant to stretching and shrinking, and has a very short drying time. |

Soy fibre is made from the by-products of soy production and tofu manufacturing, and is therefore highly resource efficient. While the production process of soy fibre is often viewed as critical due to the use of GMO soy and chemicals, the fibre itself has outstanding mechanical properties. Clothing made from soy fibre is not only highly breathable, moisture absorbent and easy to care for - it also contains amino acids which are beneficial for the human skin. |

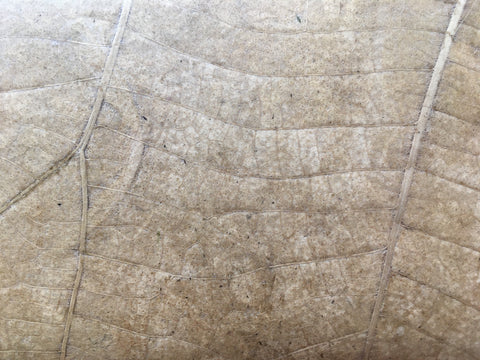

Teak leaves can be used as a plant-based alternative to leather. The fallen leaves are handpicked, dried, and covered in a fine layer of protective coating in order to make them durable and long-lasting. The process of creating this leather-like material is a traditional craft in Asian countries, particularly Thailand. Since the structure of every leaf varies, each product crafted from them is truly unique. Teak leaves can be used as a plant-based alternative to leather. The fallen leaves are handpicked, dried, and covered in a fine layer of protective coating in order to make them durable and long-lasting. The process of creating this leather-like material is a traditional craft in Asian countries, particularly Thailand. Since the structure of every leaf varies, each product crafted from them is truly unique.

|

Tencel - also known as lyocell - is a fibre from the Austrian company Lenzing. The fibre is produced from renewable cellulosic plants using an environmentally responsible production process. In most cases it is derived from eucalyptus trees, which are known to grow fast even without the use of fertilisers or pesticides. Tencel is a type of rayon, but due to its closed loop production it causes less environmental harm than conventional rayon and viscose production. The fibre produced by Lenzing is certified as compostable and biodegradable and can be integrated back into nature's cycle after its use. In addition to that, Tencel is anti-bacterial, breathable, lightweight, and highly moisture-absorbent. |

Cookies

We use cookies. Many are necessary to operate the website and its functions, others are for statistical or marketing purposes. With the decision "Only accept essential cookies" we will respect your privacy and will not set cookies that aren't necessary for the operation of the site.

Essential

Statistics & Marketing

Accept all

Only accept essential cookies

Individual data privacy settings

Save & close

Essential

Essential cookies enable basic functions and are necessary for the proper functioning of the website.

display information

Statistics & Marketing

Marketing cookies are used by third parties or publishers to display personalized advertising. They do this by tracking visitors across websites.